[ad_1]

By Dr Vikas Gupta

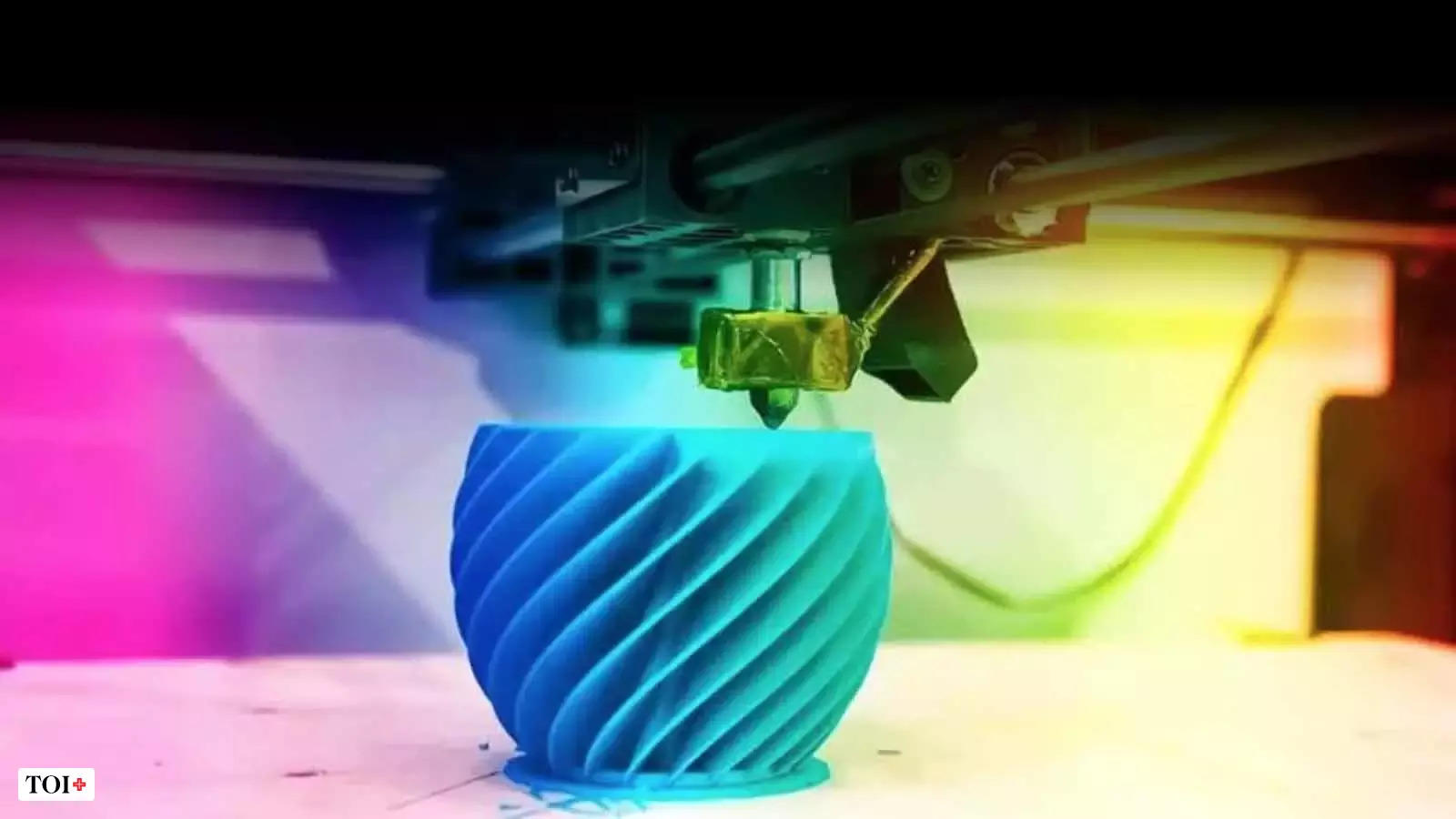

The IT revolution commenced with the appearance of the World Large Net developed at CERN, France. Since then the world has seen a speedy transformation in know-how. Inside our lifetimes, a number of applied sciences and merchandise have develop into out of date, changed by novel, proficient mechanics throughout the spectrum. And a latest technological growth that has taken the medical world by storm is 3D printing.

3D printing is a part of a household of producing know-how referred to as additive manufacturing. This describes the creation of an object by including materials to the article layer by layer. The method of 3D printing begins by making a graphic mannequin of the article to be printed. These are normally designed utilizing Pc-Aided Design (CAD) software program packages, and this may be essentially the most labour-intensive a part of the method. One of many essential advantages of 3D printing is that it permits the speedy prototyping of just about something. The one actual limitation to its utilization is your creativeness.

Some objects are just too advanced to be created in a extra conventional manufacturing or prototyping processes like CNC milling or moulding. It is usually so much cheaper than many different conventional manufacturing strategies. After the design, the subsequent part is digitally slicing the mannequin to get it for printing. The slicing course of breaks down the mannequin into many layers. The design for every layer is then despatched to the printer head to print, or lay down, so as.

As soon as the slicer program has labored its magic, the information is then despatched to the printer for the ultimate stage. From right here, the 3D printer itself takes over. It should start to print out the mannequin in accordance with the precise directions of the slicer program utilizing completely different strategies, relying on the kind of printer used. Thus, with a quick overview of the method being introduced, allow us to delve into the utilization of 3D printing in medical sciences, with an emphasis on orthopaedics.

In accordance with a examine printed within the World Well being Journal, 3D fashions manufactured by 3D printing scale back developmental prices of medical components and surgical planning time. Integrating 3D printing with orthopaedics helps in recognising and understanding the issue meticulously and ensures a larger assure of success in operations. This know-how can allow medical doctors/surgeons to design, produce, recreate and plan operations extra precisely, rigorously, and economically. 3D fashions can help specialists with a visible comprehension of the patient-particular pathology and life buildings. Innovation in 3D printing initiated a blueprint for the digital define and execution of medical procedures.

Probably the most vital alternative for 3D printing in orthopaedics is that it assists in designing exact anatomical shapes and means that permeable bone substitution platforms might be integrated into affected person implants. It takes into consideration pure bone ingrowth, guaranteeing the stability of the implant over the lengthy haul.

A number of the avenues during which 3D printing presents vital help are listed under by the writer :

Trauma instances

The orthopaedic medical process usually runs into impediments in instances with giant important wounds with completely different bone discontinuity, and in these exhibiting bone deformations, Radiographs are utilized routinely for orthopaedic surgical procedures, but they lack information on the precise 3D diploma of bone imperfections. Right here, 3D printing can efficiently be utilized in these instances because it makes use of a 3D mannequin which provides particular required outcomes/information.

Surgical planning

3D printing fashions are sometimes used to help within the surgical planning course of for restorative osteotomies, with a particular finish aim to select up a extra academic define of the life programs and to reinforce the element of arranging, significantly in situations of insignificantly intrusive medical procedures. It produces an actual duplicate mannequin of the affected person’s influenced physique organ/half, which might be seen and felt. Totally different printed fashions of the hip, knees, and shoulders can be utilized to make the custom-fitted particular design of the injured half and used as patient-specific implants.

Surgical procedure verification with reverse engineering

One other utilization of 3D printing is the identification of orthoses with the assistance of reverse engineering help with 3D scanners. This method allows a constant becoming to the affected person’s life programs and streamlines the plan’s selection and the supplies.

Personalized instruments and components

The utilization of bodily fashions for therapy arranging and notion, reasonably than the only utilization of computed tomography (CT), magnetic resonance imaging (MRI) data or digital remaking, allows the physician to picture completely different areas of the human physique with larger accuracy.

Different advantages

AM diminishes the development time by enabling amendments to an merchandise to be made forward of schedule. Speedy prototyping (RP) permits for engineering, fabricating and assembling of things on time within the deliberate process, with the aim that the misstep might be amended and adjustments might be made whereas they’re as but economical. Dr Vikas Gupta, Guide, Hand & Higher Extremity Surgical procedure (orthopaedics) At Max Hospitals, cites the instance of the process for eradicating a tumour to spotlight the advantages of utilizing 3D printing: “When eradicating a tumour, conventional strategies of utilizing a solid takes up time throughout which the tumour could develop in measurement. 3D printing successfully addresses this downside as the method is speedy.”

3D printing innovation can be utilized to enhance specialists performing programs (operative process) precisely. Even a couple of printing applied sciences can produce mechanical bones, human tissues, and organs used on to craft within the affected person physique. Printing explicit custom-made devices for sufferers might be utilized to ensure very best screw route and embed association with insignificant presentation.

Procedures akin to Templating and pre-contouring a Recon plate for acetabular fracture are manufactured by utilizing 3D printing. The consequence exhibits enchancment in surgical outcomes and lowered general surgical time. In one other case during which 3D printed jigs are used for complete knee arthroplasty, which helps to enhance general efficiency.

“Past the cost-effective, time-saving parts, 3D printing permits for patient-specific merchandise to be created, permitting for a variety of modifications to fulfill the wants of particular person sufferers. Additionally, 3D printing can be utilized in distant areas as all it requires is the printer and the fabric, thereby eliminating the necessity to carry round costly, cumbersome gear,” explains the writer. The advantages promised by 3D printing are quite a few. Nonetheless, like most trendy applied sciences, there are particular limitations in its utilization as highlighted under:

Cleansing limitations

The form alternative of 3D printing brings some new difficulties for implant creators and producers. Originators and makers want to contemplate the cleansing conditions of the devices and embed them within the strategy planning stage for the reason that super geometric flexibility could make all of the harder cleansing requests

Bio-printable supplies limitation

State-of-the-art 3D printing, significantly for the creation of implantable biomedical devices, is severely constrained by printable supplies. Thus, elective materials dealing with strategies are wanted to deal with the supplies that aren’t successfully printable.

Authorities instructions, standardization and regulatory limitations

The institutionalization of 3D printing is a steady process. At this time, administrative workplaces are getting snug with 3D printing developments. Nonetheless, they nonetheless presumably drive 3D printing– explicit requirements on restorative gadget producers till the purpose when acknowledged norms are embraced and perceived by the executive specialists.

Bio-degradability and toxicity limitation

The degradation of the supplies is a big problem within the 3D levels. The utilization of degraded supplies could lead to hypoxia and acidosis contained in the programs. The entry of acidic debasement relies upon the extent of acidosis, which can harm the seeded cells and in addition the included cells.

Whatever the limitations of this know-how, 3D printing is about to revolutionise surgical procedures. Main luminaries of the medical fraternity have voiced their help for the utilization of 3D printing. The probabilities promised are astounding and 3D printing can guarantee a far larger success charge in comparison with different existent applied sciences. And if the trajectory of technological development is any indication, one can declare that the mechanical limitations of 3D printing will quickly be overcome.

Considering the way forward for this know-how, Dr Gupta states, “Organic ink and matrix have gotten more and more prevalent. And cells might be induced to develop within the organic matrix together with stem cells. Thus, shortly organs may be printed, giving an awesome increase to the medical fraternity. Lengthy ready instances for organ transplants will quickly be a relic of the previous.” Thus, 3D printing presents a number of advantages and can quickly be an indispensable know-how within the medical fraternity.

Dr Vikas Gupta , Director – Orthopaedics and Head – Hand & Shoulder Surgical procedure, Max Hospital, Gurgaon & Max Good Tremendous Specialty Hospital, Saket.

(DISCLAIMER: The views expressed are solely of the writer and ETHealthworld doesn’t essentially subscribe to it. ETHealthworld.com shall not be accountable for any injury brought on to any individual / organisation immediately or not directly)

[ad_2]

Source link